News

-

Series classification and application of aluminum

three ××× series three ××× Series aluminum plate: mainly represents 3003, 3004 and 3A21. Also called rust-proof aluminum plate. China 3 ××× The production process of series aluminum plate is excellent. three ××× Series aluminum plate is mainly composed of manganese, with the content between 1.0-1...Read more -

Series classification and application of aluminum (Part II)

two ××× series two ××× Series aluminum plate: represents 2A16 (LY16), 2A06 (LY6). two ××× The series of aluminum plates are characterized by high hardness, of which the content of copper is the highest, about 3-5%. two ××× Series aluminum plate belongs to aviation aluminum, which is not often use...Read more -

Series Classification and Application of Aluminum

one ××× series one ××× Series aluminum plate: 1050, 1060, 1100. In all series 1 ××× The series belongs to the series with the highest aluminum content. The purity can reach more than 99.00%. Because it does not contain other technical elements, the production process is relatively simple and the ...Read more -

National Bureau of Statistics: Local rebar prices in China rose by 1.9% at the end of February

Events Our largest conferences and market-leading events provide all attendees with the best networking opportunities while adding value to their business. Steel Video Steel Video SteelOrbis conferences, webinars and video interviews can be viewed on Steel Video.Read more -

What is aluminum plate?

Aluminum plate is a kind of aluminum material. It refers to the aluminum products that are rolled, extruded, stretched and forged into plates by plastic processing method. In order to ensure the final performance of the plate, the finished product is subject to annealing, solution treatment, quen...Read more -

Difference between electrolytic copper and cathode copper

There is no difference between electrolytic copper and cathode copper. Cathode copper generally refers to electrolytic copper, which refers to the prefabricated thick copper plate (containing 99% copper) as the anode, the pure copper sheet as the cathode, and the mixture of sulfuric acid and copp...Read more -

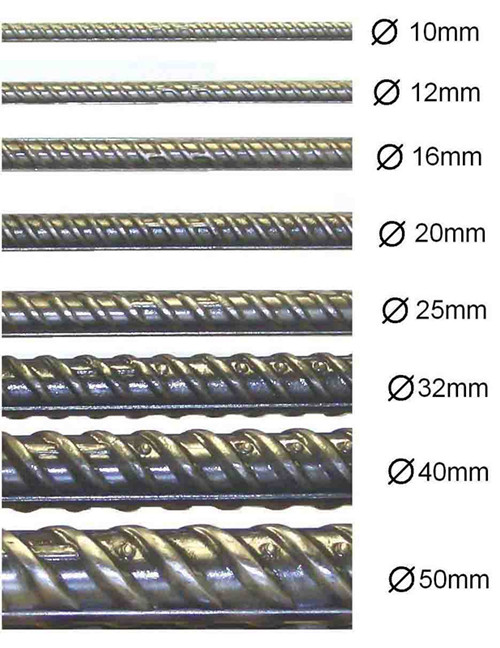

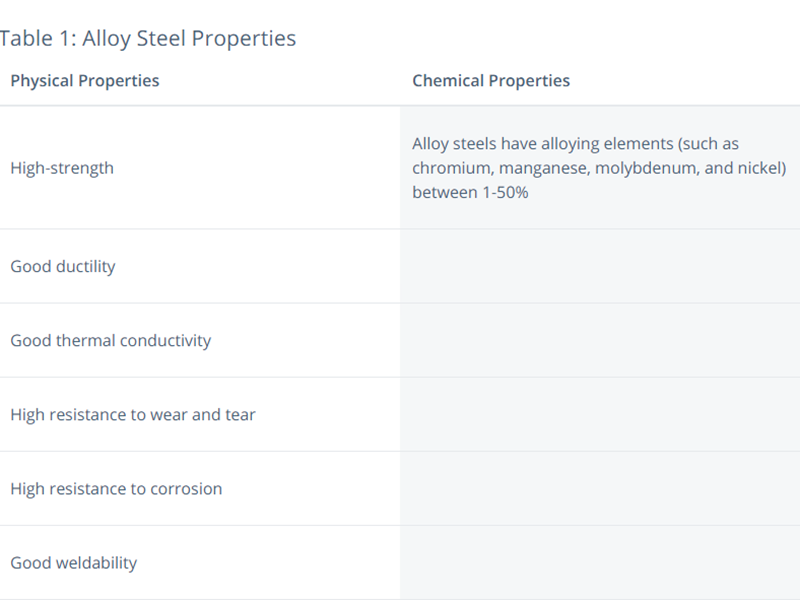

Learn the difference between alloy steel and carbon steel in detail

Both alloy steel and carbon steel have very useful properties. Carbon steel is an alloy of iron and carbon, usually containing up to 2% carbon by weight. It is often used in production: machines, tools, steel structures, bridges and other infrastructure. On the other han...Read more -

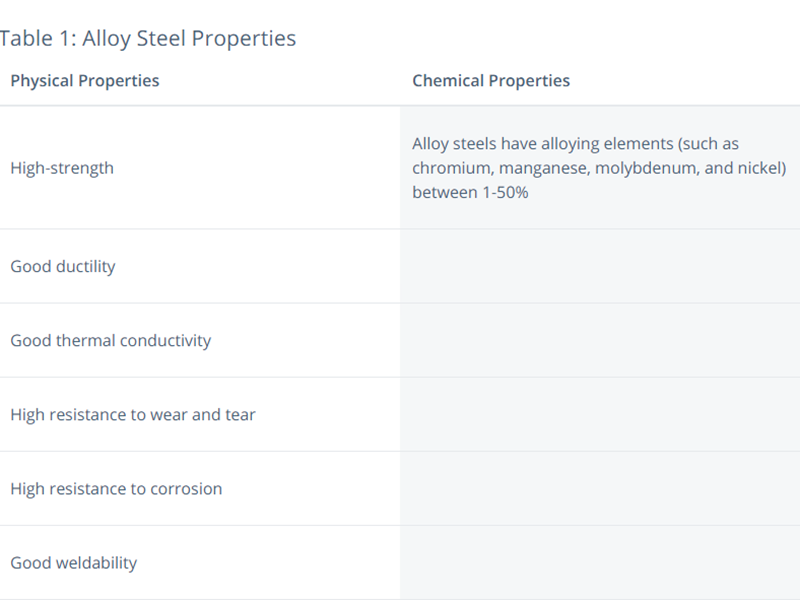

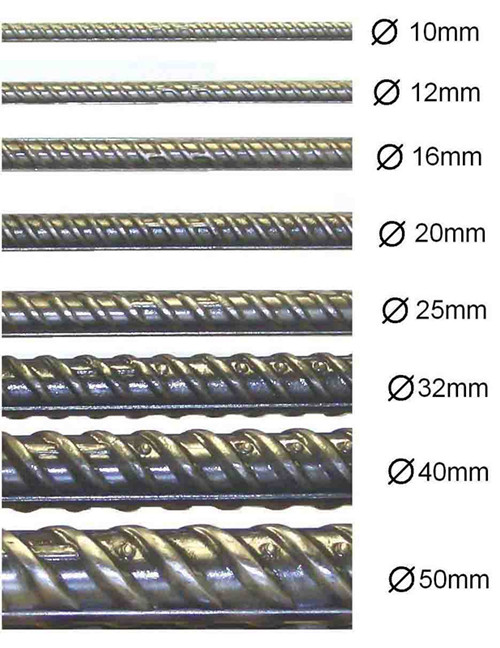

Classification of rebar

The difference between ordinary steel bar and deformed steel bar Both Plain Bar and Deformed Bar are steel bars. These are used in steel and concrete structures for reinforcement. Rebar, whether plain or deformed, helps make buildings more flexible, stronger and more resistant to compression. The...Read more -

API 5L Pipe Specification

API 5L pipe is carbon steel pipe used for oil and gas transmissions, it includes the pipes manufactured in seamless and welded (ERW, SAW). Materials covers API 5L Grade B, X42, X46, X52, X56, X60, X65, X70, X80 PSL1 & PSL2 onshore, offshore and sour services. API 5L the implementation standar...Read more -

Production process flow of hot rolled steel plate factory

According to the rolling state of the rolling mill, the production process of the sheet steel mill can be divided into two types: the hot-rolled steel plate process and the cold-rolled steel plate process. Among them, the process of hot-rolled medium plate, thick plate and thin plate in metallurg...Read more -

Production process of seamless steel pipe

Production of high-strength alloy steel pipes The production method of seamless steel pipe is roughly divided into the cross-rolling method (Mennesmann method) and the extrusion method. The cross-rolling method (Mennesmann method) is to first perforate the tube blank with a cross-roller, and then...Read more -

The production process of rebar mainly includes 6 major steps:

1. Iron ore mining and processing: There are two kinds of hematite and magnetite that have better smelting performance and utilization value. 2. Coal mining and coking: At present, more than 95% of the world’s steel production still uses the coke iron-making method invented by the British D...Read more