Ngwaahịa

-

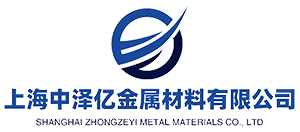

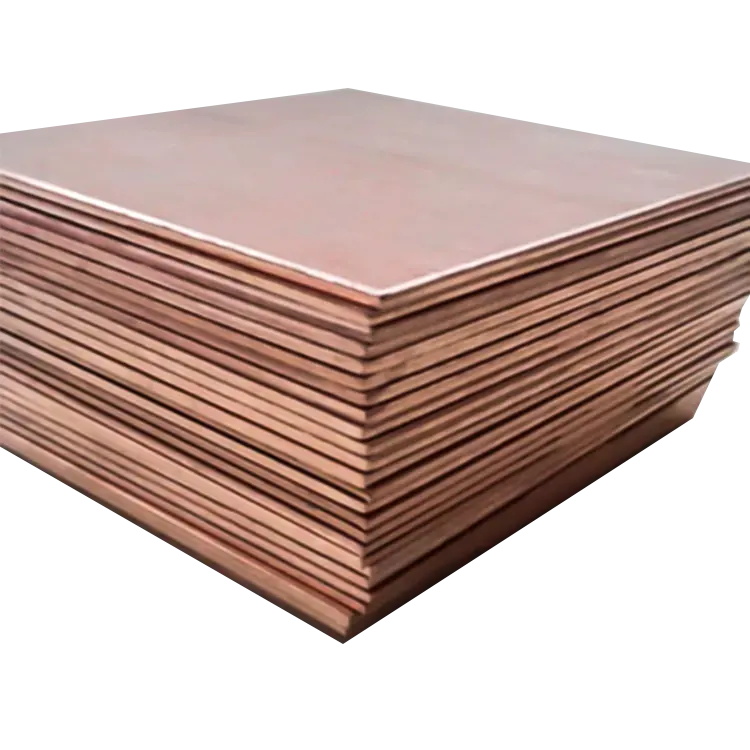

Ọla kọpa dị ọcha 3mm 5mm 20mm ọkpụrụkpụ 99.99% Copper Cathodes T2 4 × 8 ọla kọpa efere mpempe akwụkwọ soplaya

- Nọmba nlereanya: ASTM B42/68/88/280/111/640/447

- Ngwa: Ụlọ ọrụ mmepụta ihe

- Ụdị: Efere

- Obosara: 20mm-2500mm

- Ihe: Brass, Ọcha dị elu 99.9% ọla kọpa

- Ọkwa: ọla kọpa dị ọcha

- Cu (Nkeji):99.99%

- Alloy ma ọ bụ na ọ bụghị: bụ Alloy

- Ike kachasị (≥ MPa): 220-400

- Mgbatị (≥%): 45%

- Ọrụ nhazi: Ịgbado, Welding, Decoiling, Ịcha, Punching

- Elu: Na-egbuke egbuke

- MOQ: 50KG

- Oge nnyefe: 7-15 ụbọchị

- Nkwakọ ngwaahịa: Igbe osisi siri ike

- Oge ịkwụ ụgwọ: L/CT/T (30% nkwụnye ego)

- Njikwa ogo: Nyocha ndị otu

- Ihe atụ: n'efu

-

Efere Efere 3mmCT Ụlọ ihe nchebe Radiation Efere Efere DR Ime ụlọ eze nchekwa mgbidi Efere Efere Efere Efere eriri eriri akpụkpọ anụ.

Nọmba nlereanya: 001

- Ụdị: mpempe akwụkwọ

- Akụkụ: ahaziri

- Pb (Nkeji):99.9%

- Powder ma ọ bụ na ọ bụghị: Ọ bụghị ntụ ntụ

- Agba: isi awọ-ojii

- Ọganihu nhata: 0.12-1.0mmb

- Ojiji: Nchedo X-ray na-egbochi ọkụ

- Ihe: ndu

- Asambodo::Ndebanye ngwa ngwa ọgwụ klaasị II

- Ngwa: X-Ray room.CT/MRI Room,Dental Clinic,Ụlọ ọrụ,Ụlọ ọrụ mmepụta ihe

- Mgbe ọrịsịrị: Ntuziaka ntanetị n'efu

-

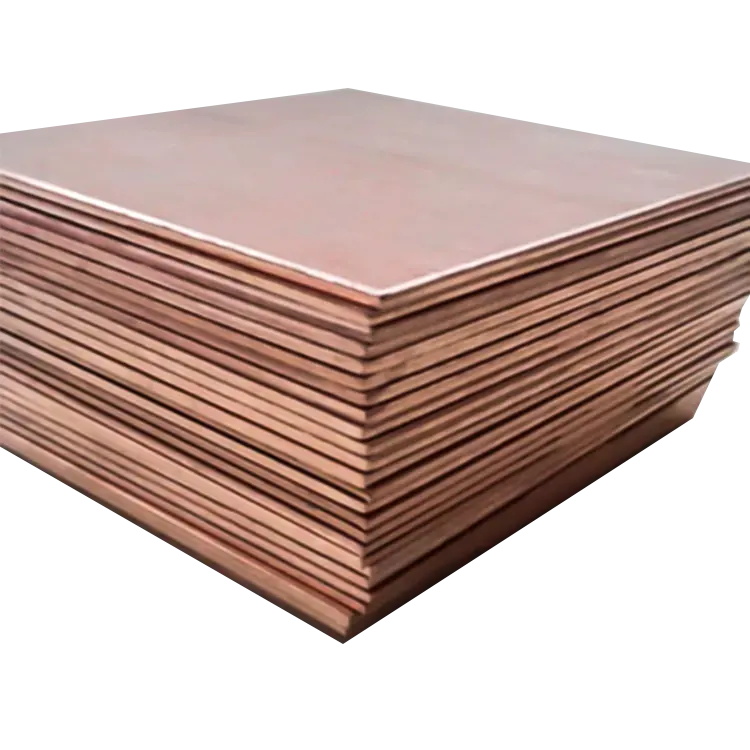

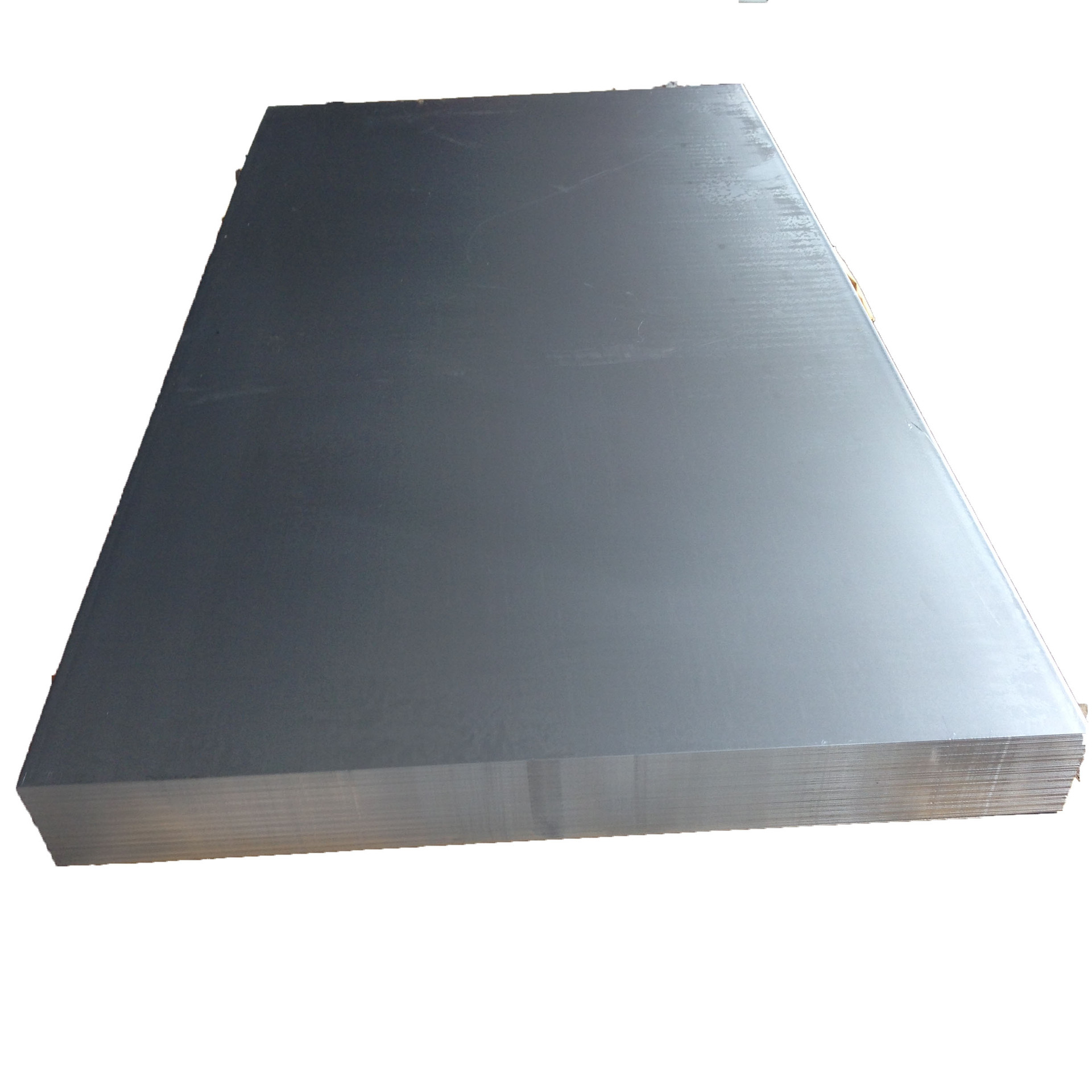

Oyi akpọrepu efere SPCC N'ogbe oyi akpọrepu efere mirror ịbịaru oyi akpọrepu eriri igwe size ọnwụ ụgbọelu thickened oyi akpọrepu ígwè efere.

- Ngwa: Ụgbọ mmiri efere, efere esi nri, efere efere, na-eme ka ọkpọkọ, na-eme ka oyi akpọrepu ígwè ngwaahịa, na-eme obere ngwaọrụ

- Ụdị: Mpempe ígwè

- Ọkpụrụkpụ: 1.2-20mm

- ọkọlọtọ: ASTM

- Obosara: 800-2500mm

- Ogologo: dị ka arịrịọ gị, 0.5-12m

- Asambodo:JIS, ISO9001

- Ọkwa: ss400

- Ndigide: ± 1%

- Ọrụ nhazi: Welding, Punching, Ịcha, Ehulata, Decoiling

- Mfefe Skin: Ee

- Alloy Ma ọ bụ Ọ bụghị: Na-abụghị Alloy

- Oge nnyefe: 7-15 ụbọchị

- Ngwọta dị n'elu: iferi, mmanụ, wdg

- MOQ: 1 ton

- Usoro: Oyi Rolled

- Ọmụmaatụ: dị

- Oge ịkwụ ụgwọ: 30% TT Ọganihu + 70% Balance

- Mbukota: Standard Seaworthy mbukota

- Ụdị ngwaahịa: Plate metal

- Ọkwa ígwè:ss400

-

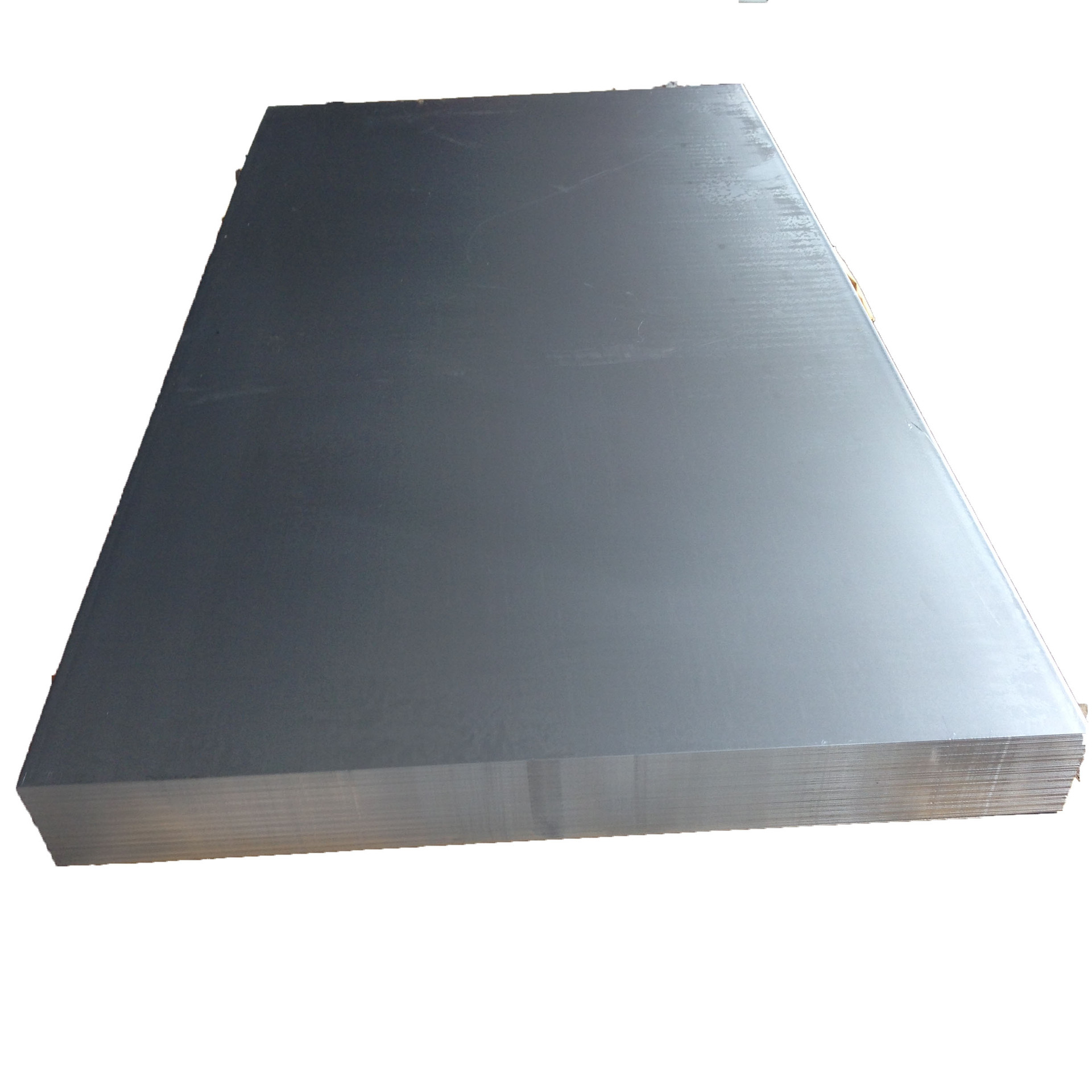

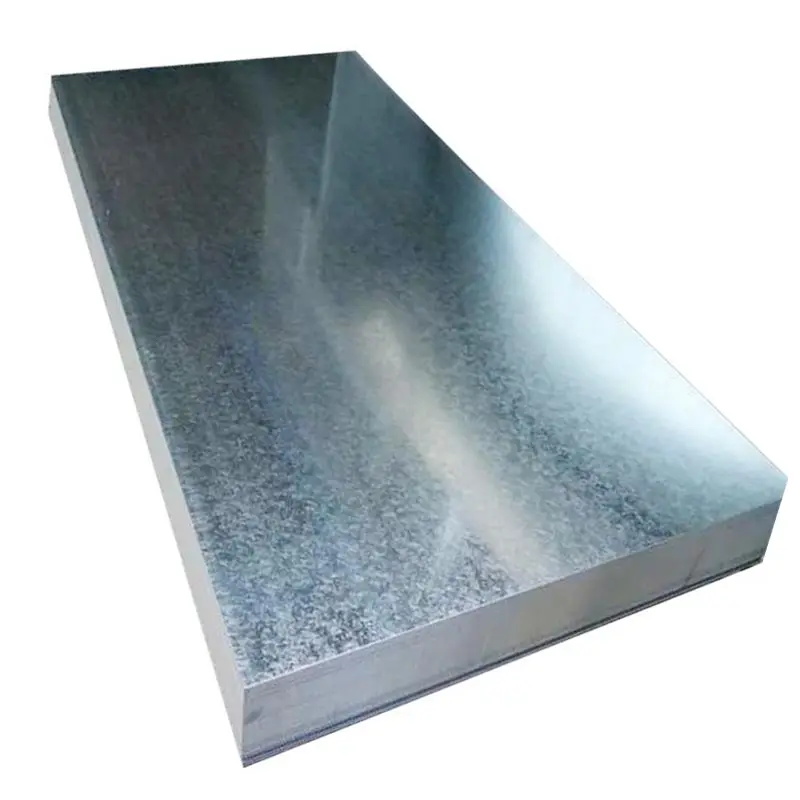

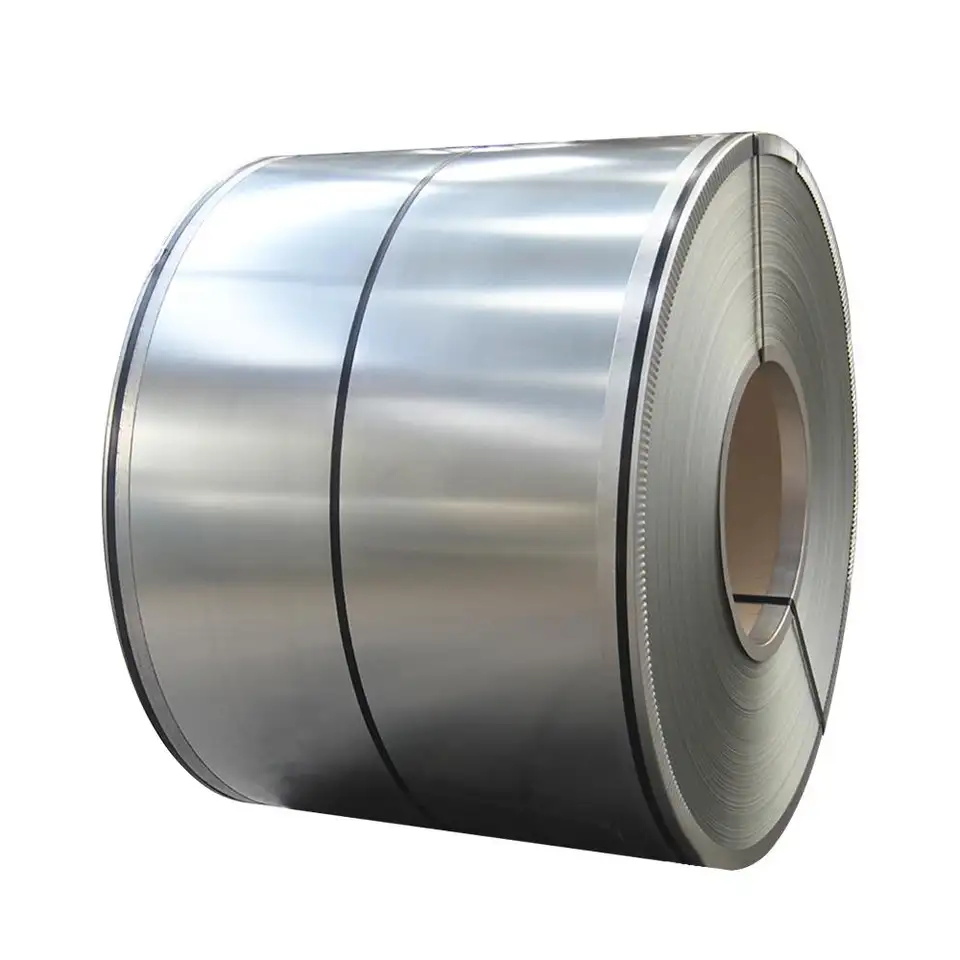

Ndị na-emepụta ihe na-enye DX51D galvanized efere galvanized ígwè ọkụ itinye galvanized eriri igwe galvanized ígwè mpempe akwụkwọ galvanized ígwè.

- Ọkọlọtọ: AiSi, ASTM, bs, DIN, GB, JIS

- Ọkwa:SGCC/CGCC/DX50D+Z/Q235/Q195, SGCC, SGCH, DX51D, Q235,Q195

- Nọmba Model:SGCC, SGCH, DX51D, Q235,Q195

- Ụdị: Plate Steel, Mpempe igwe na-ekpo ọkụ-Galvanized

- Usoro: Oyi Rolled

- Ọgwụgwọ dị n'elu: Galvanized, mkpuchi Zinc, tinye ọkụ

- Ngwa: Ihe owuwu, ngwa ụlọ, ụlọ ọrụ ụgbọ ala

- Ojiji Pụrụ Iche: Plate Steel dị ike

- Obosara: 750-1250mm

- Ogologo: na eriri igwe ma ọ bụ onye ahịa dị ka achọrọ

- Ndigide: ± 1%

- Ọrụ nhazi: Ịgbado, Welding, Decoiling, Ịcha, Punching

- Oge nnyefe: N'ime ụbọchị 7 mgbe ịkwụchara ụgwọ

- Aha ngwaahịa: Galvanized steel

- Teknụzụ: oyi na-atụ

- Ọkpụrụkpụ: 0.12mm-3.0mm

- Ọrụ nhazi: Ịgbado, Welding, Decoiling, Ịcha, Punching

- isiokwu:Galvanized Steel Sheet

- MOQ: 1 ton

- Agba: Standard Agba

- Ihe: Igwe igwe galvanized / Galvanized Steel

- Uru: Ọnụ ahịa ezi uche dị na ya na ngwaahịa bara ụba

-

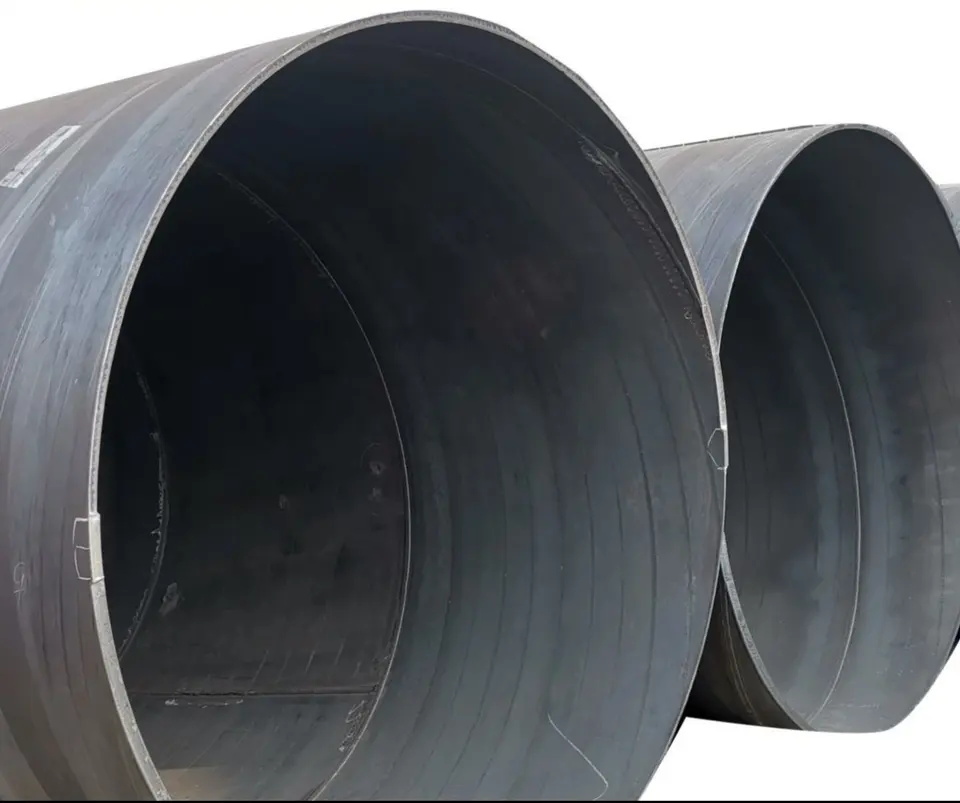

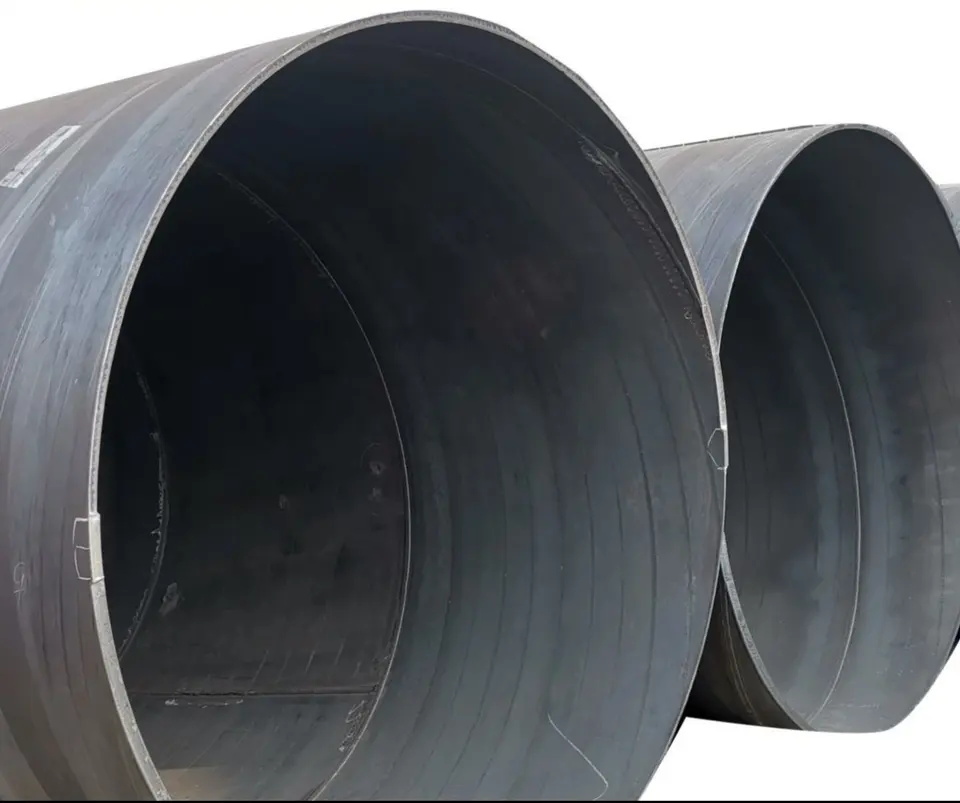

Ndị na-emepụta ihe na-enye 20G igwe ọkụ ọkụ dị elu 45# mgbidi buru ibu nnukwu dayameta ígwè ọkpọkọ efu nhazi Q235B enweghị nkebi ígwè ọkpọkọ.

A na-etinye ọkpọkọ nchara na-enweghị ntụpọ site na nchara gburugburu dum, na ọkpọkọ ígwè na-enweghị weld n'elu ka a na-akpọ ọkpọkọ nchara.Dị ka usoro mmepụta ihe si dị, a pụrụ kewaa ọkpọkọ nchara na-ekpo ọkụ na-ekpo ọkụ na-ekpo ọkụ na-ekpo ọkụ, nke na-ekpo ọkụ na-ekpo ọkụ na-ekpo ọkụ, nke na-ekpo ọkụ na-ekpo ọkụ na-ekpo ọkụ, na-ekpo ọkụ na-ekpo ọkụ, ọkpọkọ ọkpọkọ na ihe ndị ọzọ.Dịka akụkụ nke akụkụ ahụ si dị, a na-ekewa ọkpọkọ igwe anaghị agba nchara n'ime ụdị abụọ nke gburugburu na ọdịdị ya, ọkpọkọ nwere oghere nwere square, oval, triangle, hexagonal, mkpụrụ egusi, kpakpando, fin tube na ọtụtụ ụdị mgbagwoju anya.Nke kacha nta bụ 900mm na nke kacha nta bụ 4mm.Dị ka ojiji dị iche iche si dị, enwere ọkpọkọ nchara na-enweghị ntụpọ na mgbidi dị mkpa na-enweghị ntụpọ.A na-ejikarị ọkpọkọ igwe anaghị agba nchara maka ọkpọkọ mgbapu mmanụ ala, ọkpọkọ petrochemical, ọkpọkọ ọkụ ọkụ, ọkpọkọ na-ebu na ọkpọkọ nchara dị elu maka ụgbọ ala, traktọ na ụgbọ elu.

-

Stock 201/304/316L ihe Sanitary ọkwa igwe anaghị agba nchara anwụrụ polished mirror gburugburu ọkpọkọ ịchọ mma mkpa-mgbidi welded anwụrụ

- ọkọlọtọ:AISI,ASTM,DIN,JIS,BS,NB

- Nọmba nlereanya: 201 304 316

- Ụdị: enweghị nkebi/Welded

- Ọkwa ígwè: 300 Series, 310S, 316Ti, 316L, 316, 430, 304, 304J1

- Ngwa: Ụlọ ọrụ

- Ogologo elu: 100mm

- Ndigide: ± 1%

- Ọrụ nhazi: Ịgbado, Welding, Decoiling, Punching, Cutting, Molding

- Ọkwa:300 Series

- Ụdị ngalaba: Gburugburu

- Alloy Ma ọ bụ Ọ bụghị: Na-abụghị Alloy

- N'elu imecha: Polishing, ntutu ahịrị, pickling, NO.1, wdg

- Invoicing: site na usoro iwu ibu

- Oge nnyefe: ụbọchị 7

-

Nyefee nnukwu dayameta gburugburu welded ọkpọkọ 3pe atọ mmanụ abụọ akwa plastic drainage na mgbochi corrosion kpọmkwem lie gburugburu nchara anwụrụ

Ọkpụkpọ nchara welded, nke a makwaara dị ka ọkpọkọ welded, bụ ọkpọkọ igwe emere nke efere igwe ma ọ bụ nchara nchara ka crimping na ịgbado ọkụ, n'ozuzu 6 mita.welded ígwè ọkpọkọ mmepụta usoro dị mfe, elu mmepụta arụmọrụ, iche iche nkọwa, obere akụrụngwa ego, ma n'ozuzu ike dị ala karịa enweghị nkebi ígwè ọkpọkọ.

-

Igwe mkpuchi igwe anaghị agba nchara QSTE460TM adịchaghị maka Crossbeams akpaaka

A na-eji slab (nke kachasị nkedo billet na-aga n'ihu) dị ka akụrụngwa, nke a na-ekpo ọkụ ma mee ka ọ bụrụ warara site na igwe igwe na-emecha ihe na igwe ihe.A na-eme ka eriri igwe na-ekpo ọkụ na-ekpo ọkụ na-ekpo ọkụ site na igwe ihe igwe ikpeazụ na-eme ka ọ dị mma ka ọ dị mma site na mmiri laminar, na eriri igwe na-apịa ya site na igwe mkpuchi.A na-edozi eriri eriri igwe jụrụ oyi site na ahịrị mmecha dị iche iche (ịkwalite, ịgbatị, ịcha obe ma ọ bụ ogologo ogologo, nyocha, nha, nkwakọ ngwaahịa na akara, wdg) dị ka mkpa dị iche iche nke ndị ọrụ si dị.

N'ikwu ya n'ụzọ dị mfe karị, otu mpempe akwụkwọ billet na-ekpo ọkụ (ya bụ, nchara na-acha uhie uhie na nke na-ekpo ọkụ nke a na-agba na TV) wee tụgharịa ọtụtụ ugboro, wee kpụzie ya ma gbatịa n'ime efere ígwè, nke a na-akpọ ịgbagharị ọkụ. .

N'ihi ike ya dị elu, ịdị mma siri ike, nhazi dị mfe na ezigbo weldability, a na-eji ngwaahịa na-ekpo ọkụ na-ekpo ọkụ na-ekpo ọkụ na ụgbọ mmiri, ụgbọ ala, akwa akwa, ihe owuwu, ígwè ọrụ, ụgbọ mmiri nrụgide na ụlọ ọrụ mmepụta ihe ndị ọzọ.

Site na ntozu oke nke teknụzụ njikwa ọhụrụ dị ka nha nha nha, ọdịdị na ịdị mma elu nke mpịakọta na-ekpo ọkụ na ọbịbịa nke ngwaahịa ọhụrụ, a na-eji ihe ndị na-ekpo ọkụ na efere efere na-emewanyewanye ma nwee asọmpi siri ike na nke siri ike na ahịa.

-

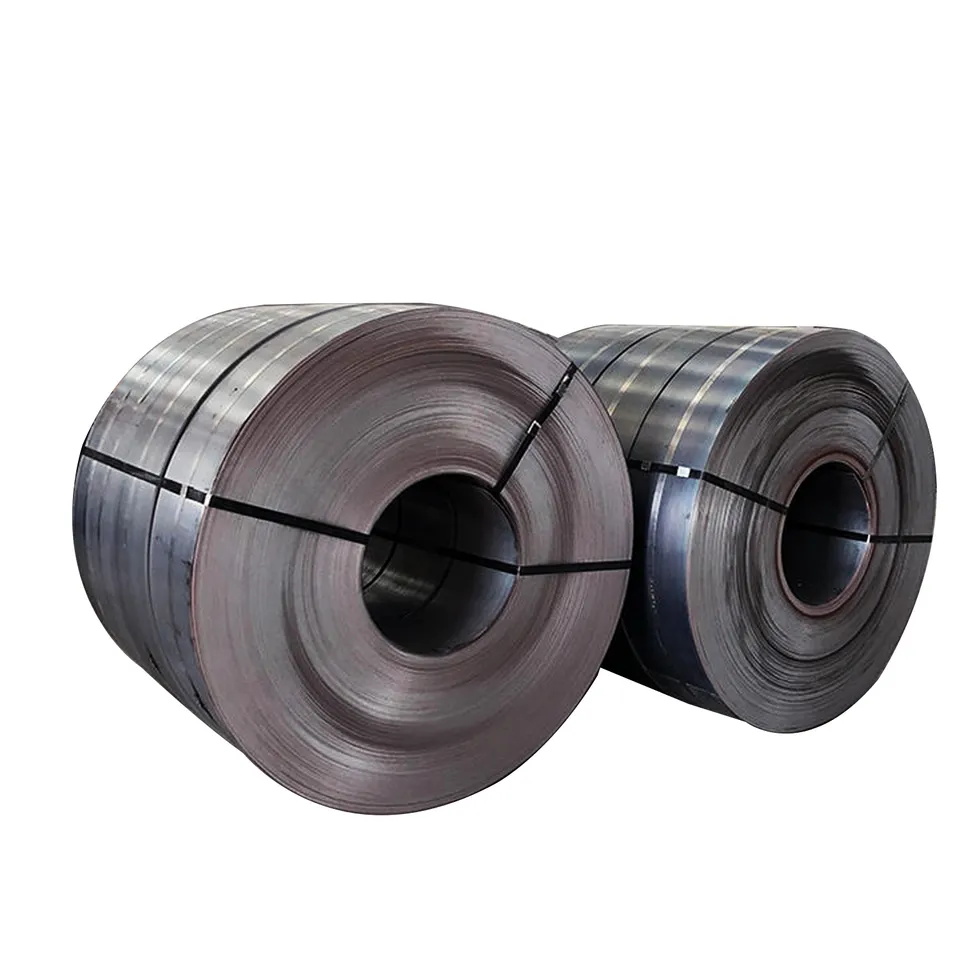

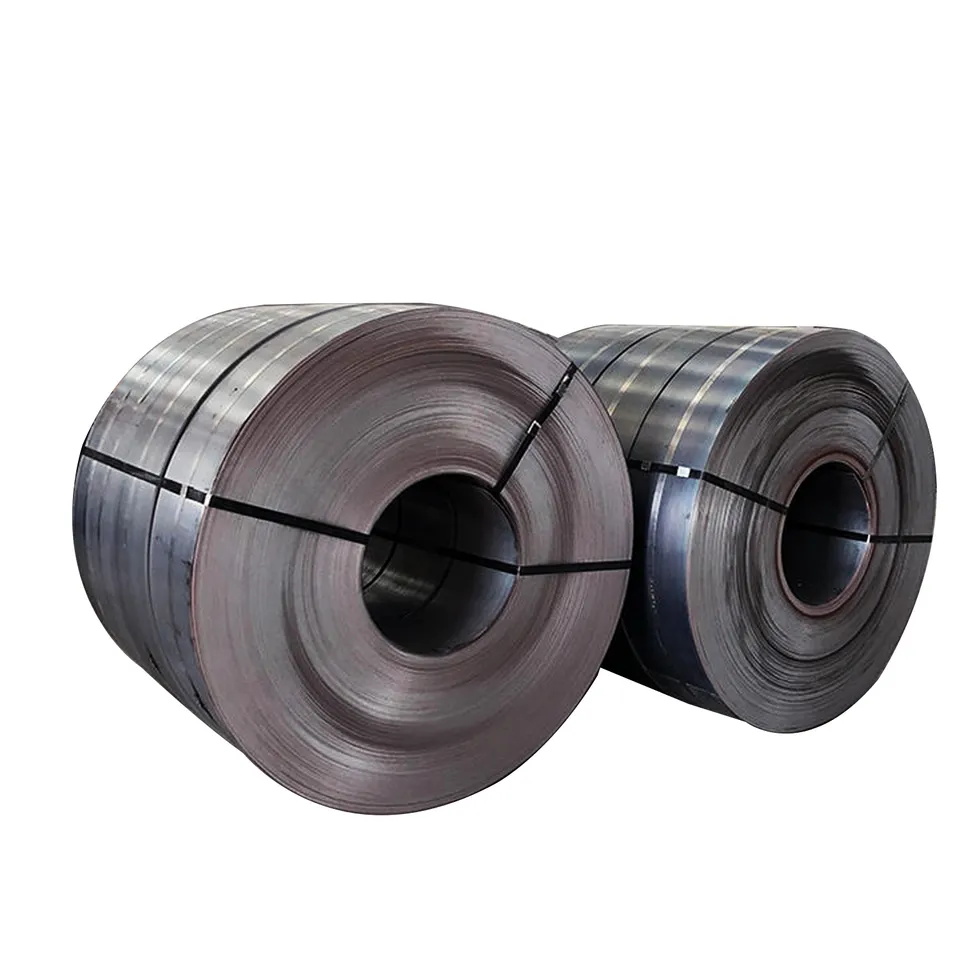

q235 pickled mmanụ ọkụ akpọrepu carbon ígwè eriri igwe astm a283 carbon ígwè eriri igwe

Pickling Coil, bụ ụdị ígwè dị iche iche na-emepe emepe, ahịa a na-achọkarị na ụlọ ọrụ ụgbọ ala, ụlọ ọrụ Compressor, ụlọ ọrụ na-emepụta igwe, ụlọ ọrụ na-ahazi akụkụ ahụ mapụtara, ụlọ ọrụ fan, ụlọ ọrụ ọgba tum tum, arịa ụlọ, ngwa ngwaike, shelf kabinet eletrik na dị iche iche. ụdị nke stamping akụkụ.Site na ọganihu nke teknụzụ, efere pickling na-ekpo ọkụ etinyewo aka na ngwa ụlọ, arịa, ebe a na-ahụ maka ọkụ eletrik na ụlọ ọrụ ndị ọzọ, n'ime nke a na-eji efere pickling na-ekpo ọkụ kama efere oyi amalitela ngwa ngwa na ụfọdụ ụlọ ọrụ.

-

Prime mma kacha mma ọnụahịa ss304l igwe anaghị agba nchara na-emepụta maka iwu ụlọ

Igwe anaghị agba nchara 304 bụ igwe anaghị agba nchara chrome-nickel nke a na-ejikarị eme ihe, dị ka nchara a na-ejikarị eme ihe, nwere ezigbo nguzogide corrosion, nguzogide okpomọkụ, ike dị ala na ihe eji arụ ọrụ;Stamping, ekwe na ndị ọzọ na-ekpo ọkụ nhazi ọma, ọ dịghị okpomọkụ ọgwụgwọ hardening onu (jiri okpomọkụ -196 ℃ ~ 800 ℃).Nguzogide corrosion na ikuku, ma ọ bụrụ na ọ bụ ikuku ụlọ ọrụ mmepụta ihe ma ọ bụ ebe mmetọ nke ukwuu, ọ dị mkpa ka ihicha ya n'oge iji zere mmebi.Kwesịrị ekwesị maka nhazi nri, nchekwa na njem.Ọ nwere ezi processability na weldability.Plate okpomọkụ Exchanger, ife t ọkpọkọ, ngwá ụlọ (1,2 ụdị tableware, cabinets, ime ụlọ pipeline, mmiri heaters, ji esi mmiri ọkụ, bathtubs), akpaaka akụkụ (windshield wipers, mufflers, ịkpụzi ngwaahịa), ọgwụ akụrụngwa, ụlọ ihe, chemicals. , ụlọ ọrụ nri, ọrụ ugbo, akụkụ ụgbọ mmiri, wdg.304 igwe anaghị agba nchara bụ ọkwa nri nke mba a ma ama nke igwe anaghị agba nchara.

-

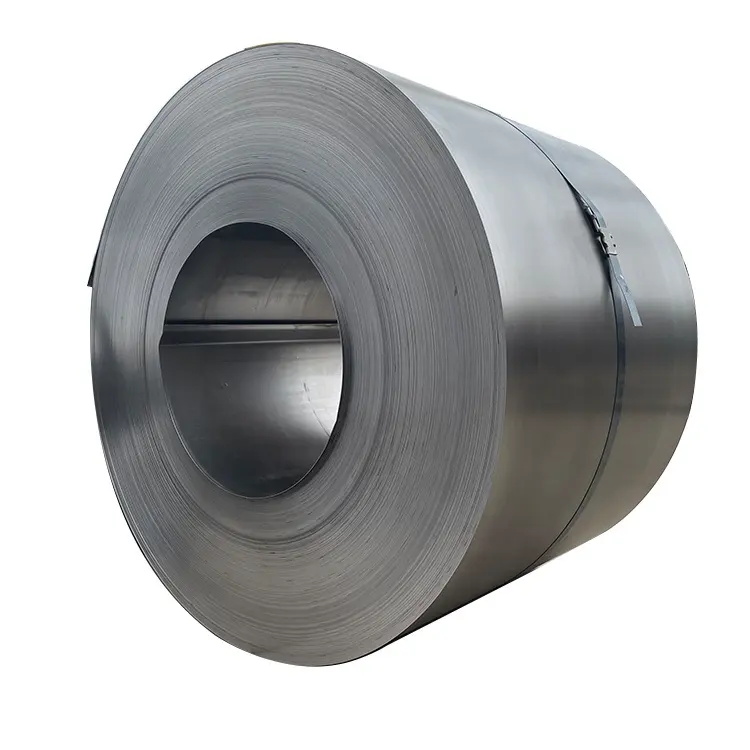

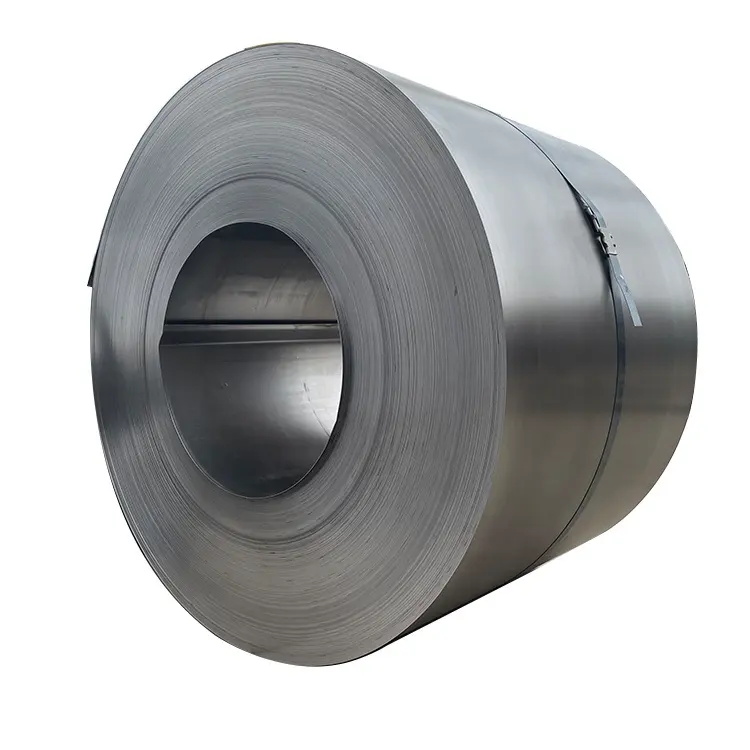

DC01 nkịtị oyi akpọrepu eriri igwe SPCC oyi akpọrepu efere ST12 hc340la oyi akpọrepu efere oyi akpọrepu nchara.

DC01 Oyi akpọrepu nchara DC01 bụ oyi na-emekarị oyi akpọrepu ígwè.Nke a bụ ígwè dị nro nwere ike mkpụrụ dị ala.Nke a na-eme ka ọ dị mma maka ojiji na ngwa ebe ike na-adịghị mkpa, dị ka na akpaaka ogwe na ngwa.Ọdịnaya carbon dị ala pụtakwara na DC01 nwere ductility dị elu, na-eme ka ọ dị mfe ịmepụta na weld.Ọ bụ ezie na DC01 dị n'ụdị mpempe akwụkwọ na eriri igwe, ọ bụ ụdị mpempe akwụkwọ a na-ahụkarị.Ọ nwekwara ụdị ọkpụrụkpụ dị iche iche, site na nke dị gịrịgịrị ruo na oke oke.A na-ejikarị ígwè na-agba oyi eme ihe na ngwa ebe nkenke na njedebe elu dị mkpa.Akụkọ ihe mere eme nke DC01 Cold Rolled steel Akụkọ ihe mere eme nke DC01 igwe oyi na-atụ bụ akụkọ dị ogologo na mgbagwoju anya.Ntugharị oyi bụ usoro a na-esi na-agafe nchara site na mpịakọta na okpomọkụ dị n'okpuru recrystallization.Nke a na-enye ohere ka ígwè ahụ jigide ọdịdị ya ma nwekwuo ike.

-

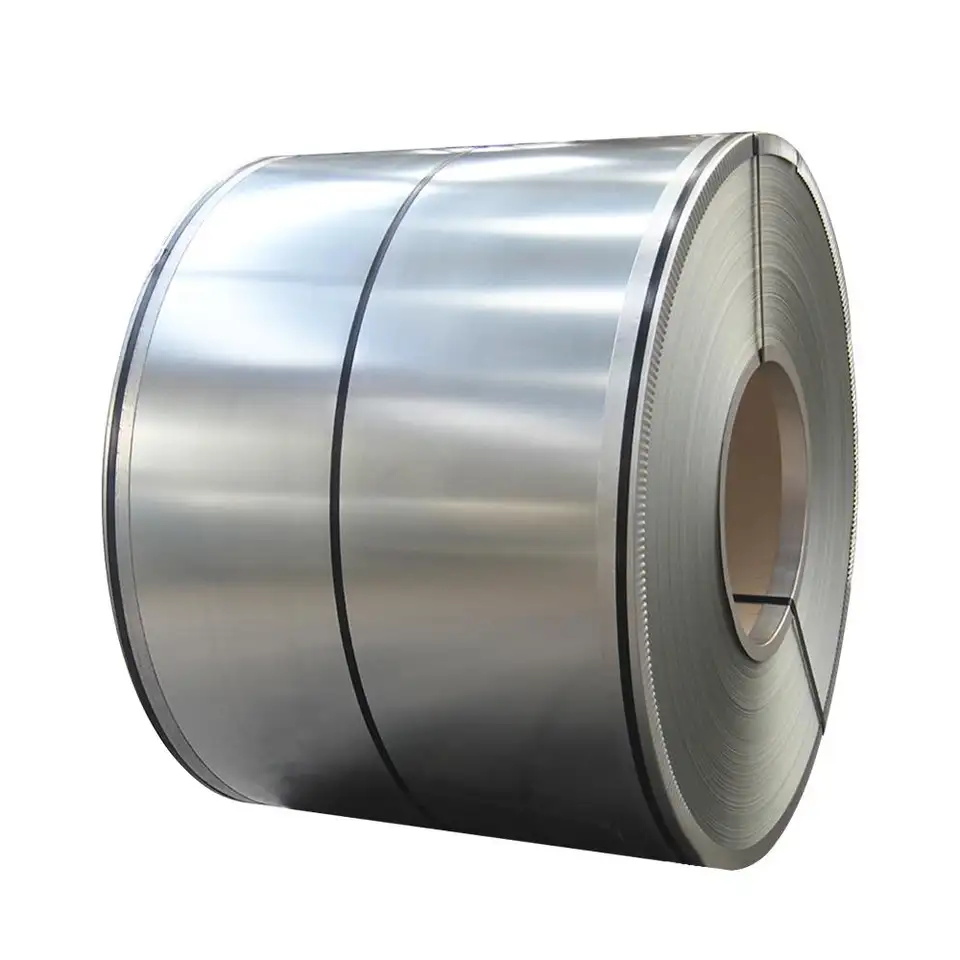

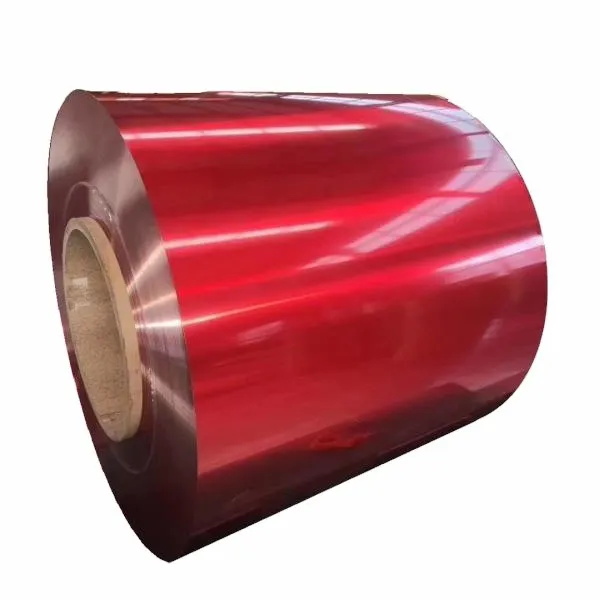

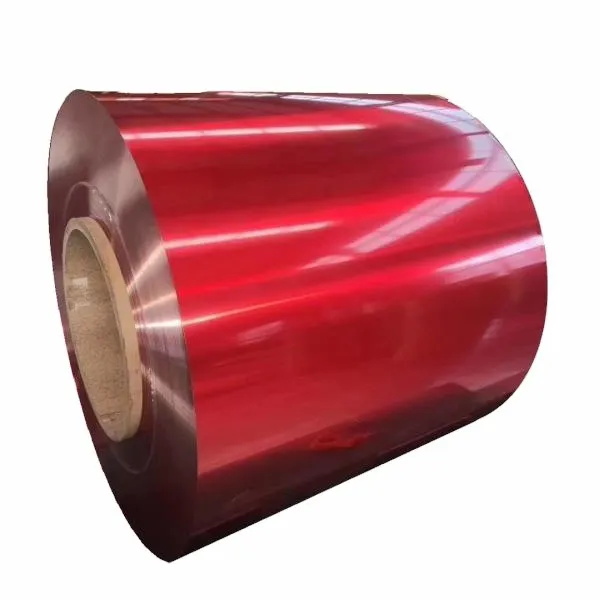

Thermal mkpuchi nano eriri igwe agba kpuchiri ígwè eriri igwe anticorrosion na-emepụta na-enye ọnụ ọgụgụ buru ibu nke thermal mkpuchi agba agba mkpuchi ígwè igwe.

Igwe mkpuchi agba agba bụ ngwaahịa nke efere galvanized na-ekpo ọkụ, aluminum na-ekpo ọkụ na-ekpo ọkụ, efere zinc, efere electrogalvanized, wdg, mgbe emechara elu (chemical degenreasing and chemical converting treatment), kpuchie ya na otu ma ọ bụ ọtụtụ n'ígwé nke organic mkpuchi n'elu, na mgbe ahụ. sie ma gwọọ ya.N'ihi na agba agba dị iche iche nke organic agba agba ígwè eriri igwe akpọrọ aha, nke a na-akpọ eriri mkpuchi agba.Na mgbakwunye na mkpuchi mkpuchi zinc, ihe mkpuchi organic na oyi akwa zinc na-ekpuchi ma na-echebe eriri ígwè ahụ iji gbochie nchara, na ndụ ọrụ dị ihe dịka 1.5 ugboro karịa nke eriri galvanized.